How To Solder Copper Wires Together

/close-up-man-hands-soldering-audio-cable-with-xlr-connector-1078041206-472dd1f03b084f2b9ab373c9dff8080e.jpg)

Do this very carefully slowly and make sure to test the melting point of the material.

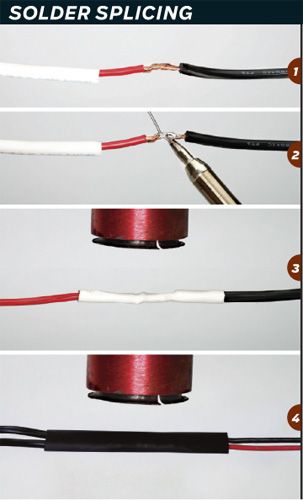

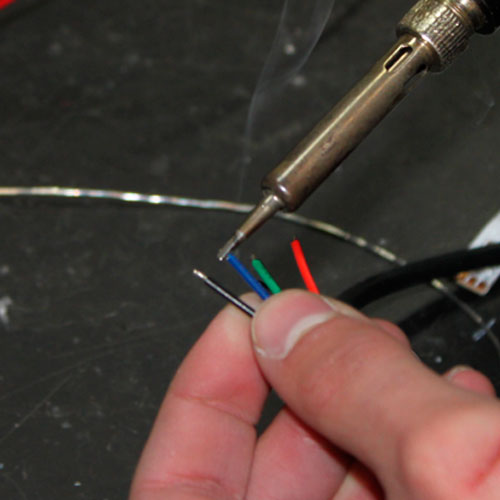

How to solder copper wires together. They DO make a COP-ALUM crimp splices for such application. Soldering The Header Tip And Wire Together. This will heat the wire to allow your solder to melt.

Now we will bring the hot iron tip to this joint to melt the metal a little bit. Move it around the parts where you are going to place the solder afterwards. Clean and deburr your pipe and fitting as you would for regular copper pipe soldering.

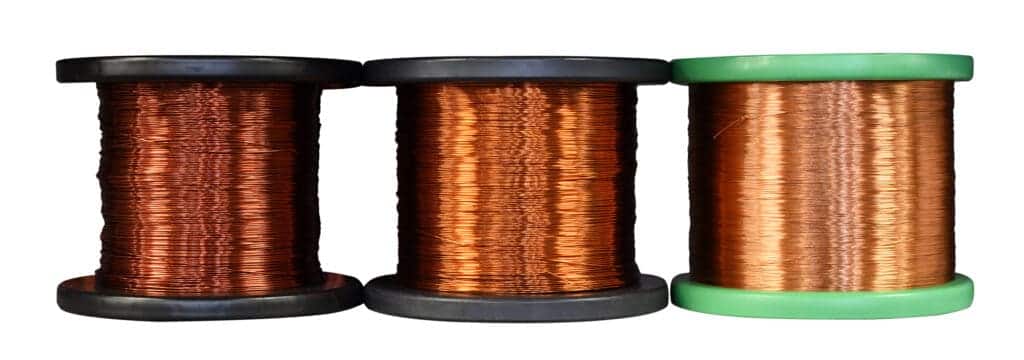

When working with large amounts of copper wire outside of electronics it may be beneficial to apply solder flux either purchased or made at home from rosin and alcohol before proceeding. Touch the tip of the soldering iron to the copper wires. Lay them together overlapping at the soldered part then blob them together.

Apply the tip of the soldering iron to the wet sponge to make the tip clean. This is probably the best solution for lights and other non outlets. Let dry per the manufacturers instructions.

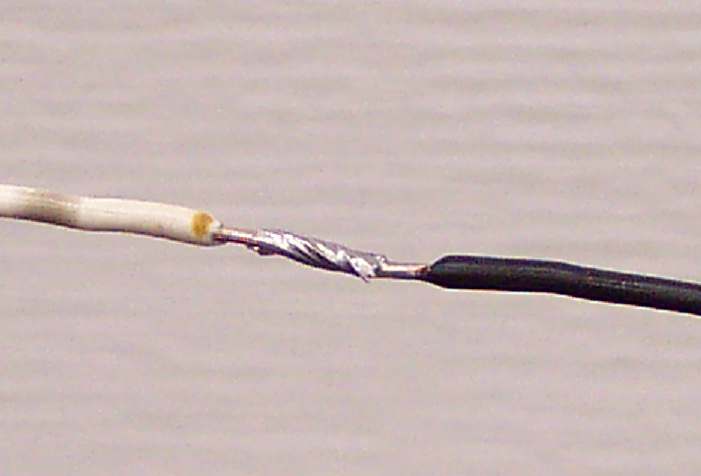

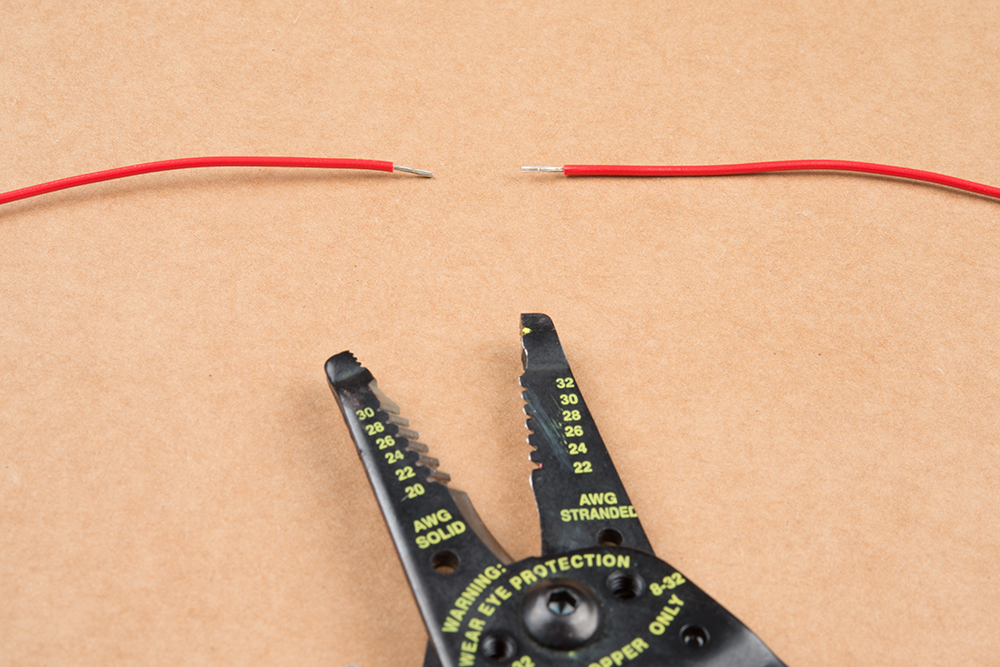

Connect together stranded wire and solid wire as shown in the third picture Use a thin solid wire 28 AWG-30 AWG and wrap it around both wires. For soldering 14ga or 12ga solid copper antenna wires together I use a cheap 15 hardware store propane torch throttled to a fairly low flame and a doubled- or tripled- length of fluxcore solder to quickly get enough wetting into the join. I dont believe there is any way to join them directly together via a typical soldering connection.

Your solder will be applied opposite from the iron on top of the wire. For this process its recommended to use helping hands or other type of clamp device. A simple terminal block version tooTheres also a COP-ALUM strip that you solder aluminum wire to one side and copper to the other side.