How To Solder Boat Trailer Wires

This is the standard way I try to connect any two wires together.

How to solder boat trailer wires. Once the connector is stamped cut and annealed its then tin-plated yielding superior corrosion protection. Sadly most wiring problems are the result of a cascading series of events that can have you tearing your hair out especially if its 4 am. Push one wire all the way through the connector then overlap the bare ends of the wires to be connected do not twist them.

Sent from my GT-I8730T using Tapatalk. Then apply heat making sure you keep rotating the wires so it doesnt get too hot too fast in one spot. My boat trailer beeps.

Once cool inspect the union to ensure proper penetration of the solder. Then slide the connector back over the overlapped wires until the solder ring is directly over them. Tap the end of the 6337 solder on top of the wire splice so the solder melts down into the wires.

Slide canister over join and fill with sikaflex and put lid on. I usually carefully strip about 20mm of the insulation off the selected wire wrap the stripped end of the wire to the trailer tightly around the stripped section of the selected wire solder it up with an electric iron resin cored solder wire then tape it up with electricians tape tuck it back into the sub frame sections or use cable ties to do a neat job. Solder wires cover with shrink tubing.

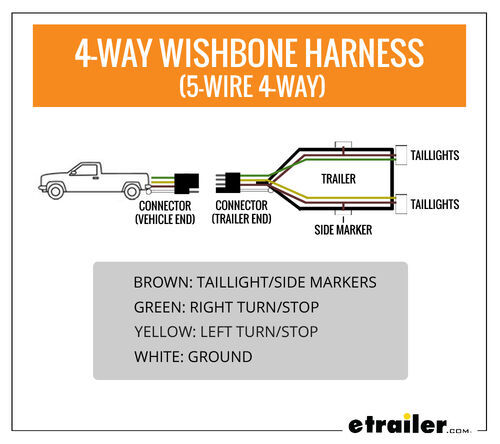

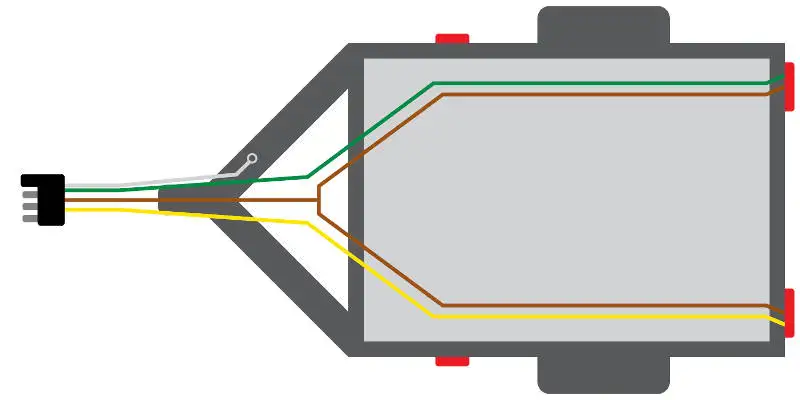

Blue Electric Brakes or Hydraulic Reverse Disable See Blue Wire Notes below In the Trailer Wiring Diagram and Connector Application Chart below use the first 5 pins and ignore the rest. 4 Wire Boat Trailer Wiring Diagram People understand that trailer is a car comprised of rather complicated mechanics. At worst try RA Rosin Active flux.

Cut off about 12 and strip and see if the wire is better looking. Then take the two ends and push then directly into each other. Use the old wires to pull.