How To Prepare Soldering Flux

It is basically used to clean surface of PCB before soldering process.

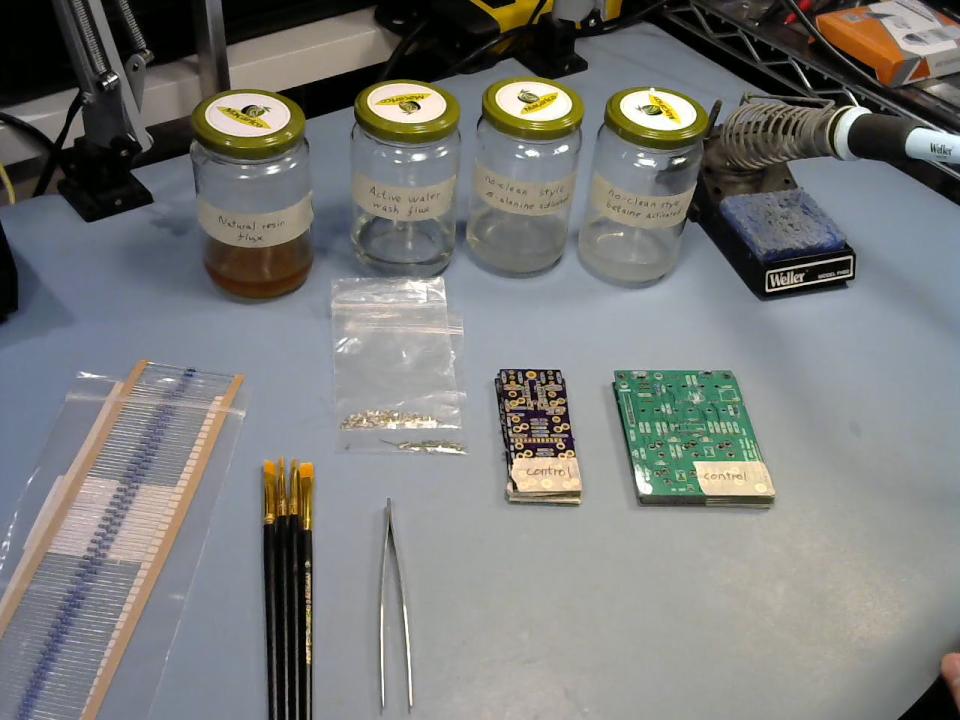

How to prepare soldering flux. We try it out and then test it by soldering a 28pin SOIC chip. Tinning will also help to protect the tip and reduce wear. Make sure the soldering iron is hot.

The tinning process protects the tip from oxidation reduces wear and enhances heat transfer. If there is a coating over the metal it will have to be removed. The flux required a preheat temperature of 100 to 130C on the topside of the board just before soldering.

Removing Coating From Metal. Rosin Flux is manufactured from a type of Resin obtained from pines and some other plants. Do not touch it.

Then it needs to apply an even coat of the flux to the surfaces where the actual soldering is. How to Solder Step By Step. In previous videos we compared different types of commercial flux but did you know its possible to make a simple and effective flux at home.

Before you start soldering ensure your materials and hands are clean of oils and grease. Important variables such as ambient temperature local code guidelines and any jobsite time limitations should all be considered prior to purchasing your soldering supplies. You should clean the metal contact with a good solvent before using the soldering flux so that remove the dust grime as well as excessive oxidation that may be present.

Will create a barrier between the metal and the solderThink of the dirty surface like plastic wrap over your ham sandwich your potential solder join. Stir the juice in the container for 10 seconds with the wooden spoon. It seals out air thus preventing further oxidation and by facilitating amalgamation improves wetting characteristics of the liquid solder.