How To Improve My Tig Welding

Use clean dry filler rod.

How to improve my tig welding. TIG can be used to weld copper titanium even two dissimilar metals and is handy for making tricky welds eg. Some tips that will help you use direct current to TIG weld aluminum are. It will weld another and easier.

TIG generates heat via an arc of electricity jumping from a tungsten metal electrode to the metal surfaces you intend to weld - usually aluminum. One of my first jobs was welding aluminum in a factory and every piece to be welded got an acid bath before welding. Re-shape your electrode as needed to get the best weld possible.

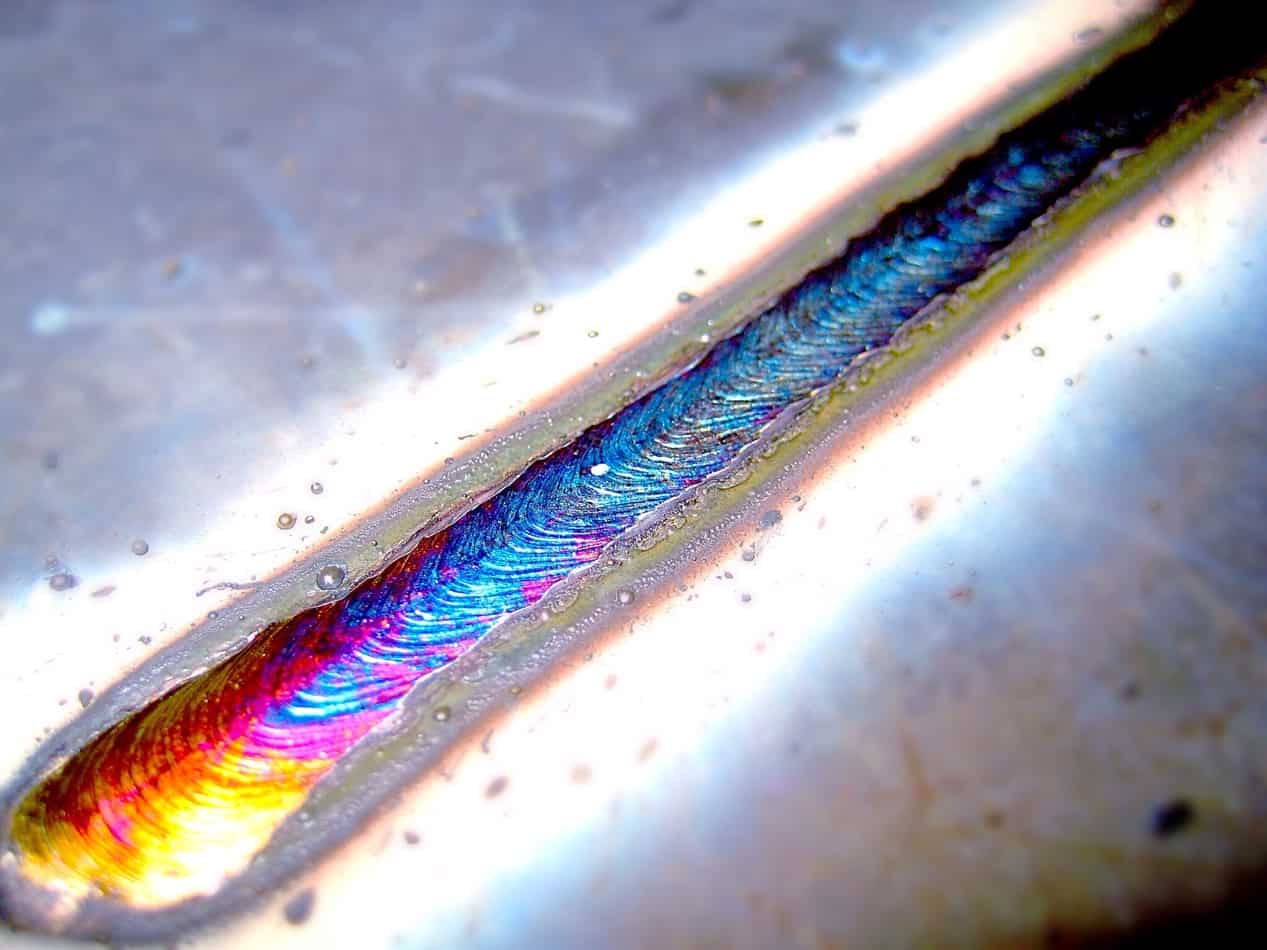

Tig welding can produce beautiful looking welds and more importantly x-ray quality deposits on some of the most critical welding applications. Excessive heat can distort the end of the electrode and cause problems with the weld. TIG welding requires proper shape for the electrode tip.

Some welds work better with a point while others need a rounded tip. I keep an assortment of wood and metal blocks near my welding bench and I often can get better support by positioning a block to rest my torch hand on. S-curves or welds on round things.

Inverters operate by switching high-voltage low-amperage alternating current AC into direct current DC back and forth at a very. TIG welding must be operated with a constant current power source either DC or AC. Invert the process.

Hold the rod so it rests horizontally at approximately a 15-degree angle to the workpiece. I learned to TIG weld by holding the torch in my right hand and moving the torch from right to left while feeding filler with my left hand. Relatively new to Tig welding any advice on how to improve would be greatly appreciated.