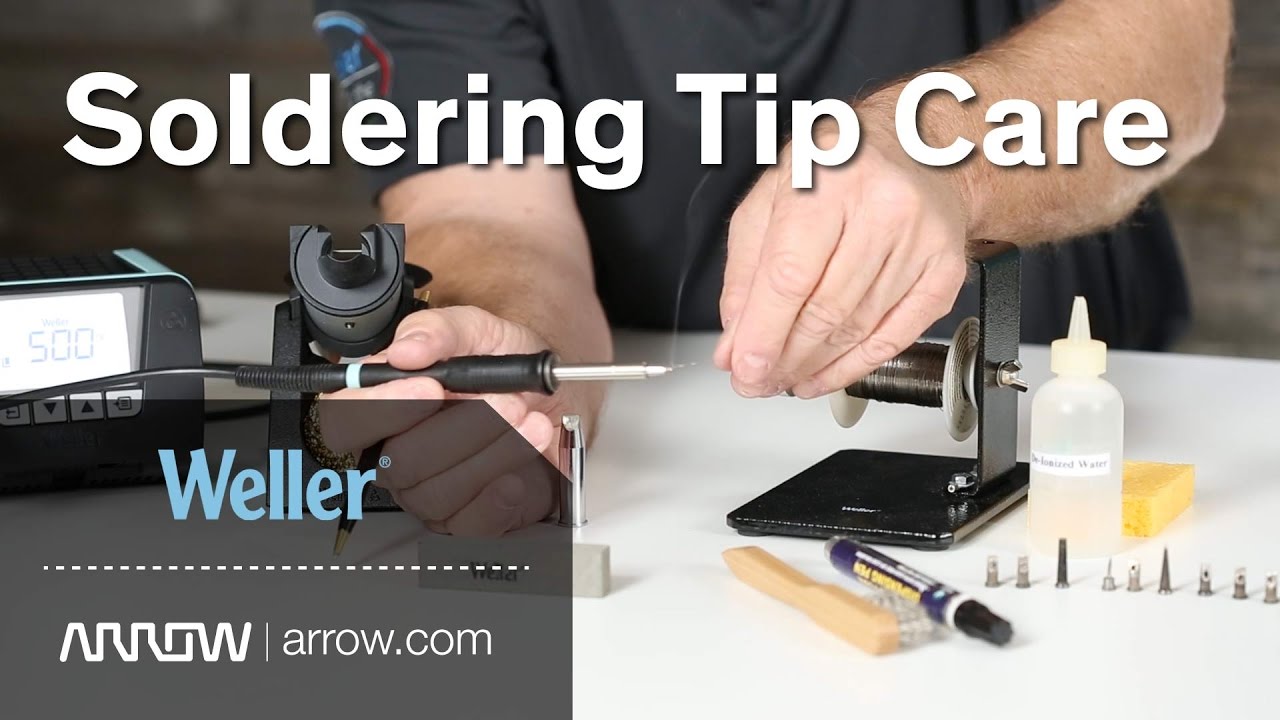

How To Clean Weller Soldering Tips

If your soldering tip becomes detinned oxidized it can be restored in a number of ways.

How to clean weller soldering tips. Using a wet sponge will reduce the heat of the tip. A screwdriver from this KC 6 Piece Screwdriver Set would work fine. I use a standard Weller iron and the tips lasts for many years some of my tips are close to 15years old.

This will allow you to clean the device as thoroughly as possible without risking burns. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Clean hot tip thoroughly with damp sponge.

Melt some good quality of solder wire on the Tip. I agree its new and you shouldnt be having problems like this. Increase tool safety and stability with the slip-resistant silicone holder.

If the tip is interchanged with different sizes frequently. Touch the solder wire to the end of the heat tip and allow the solder to color or melt onto the tip. Repeat the Process 3-4 Times until the Soldering.

Turn off your solder iron and let it cool down for 15-20 minutes before cleaning the tip. These are used to replace any damaged tips and each tip serves a different purpose. The Weller fi WLC100 uses the ST series tips.

Apply enough solder to cover the contact pad and surround the lead. Unscrew the locking nut that holds the tip-retaining sleeve and tip in place. Wipe the tip of the soldering iron on a damp wet sponge to clean it.