Soldering Iron Tips Wear Out

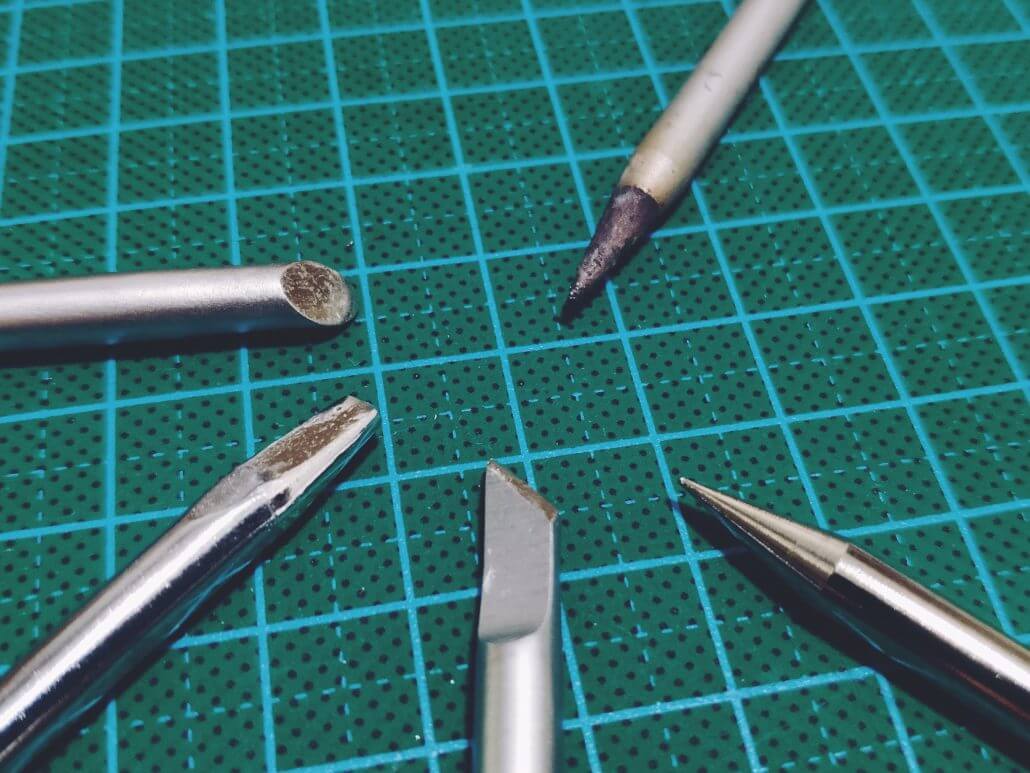

A soldering iron tip is beyond any hope of effective cleaning or repair if any part of the iron tip no matter how small has worn all the way through.

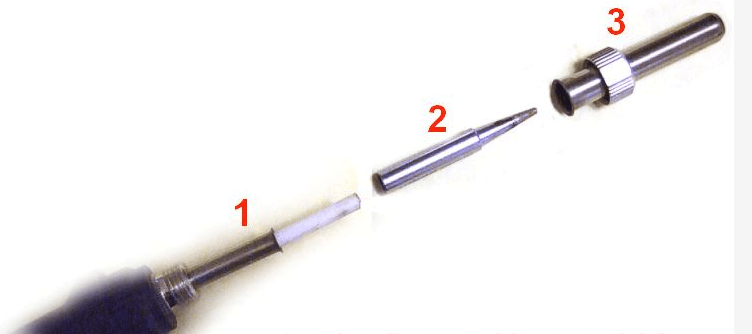

Soldering iron tips wear out. Instead have the solder pads free of oxididized surfaces meaning to remove any protective film shortly before soldering. Soldering Iron tips do not last forever. First theres the one commonly known as a b-series tip.

NEVER file a soldering tip. Corrosion from acidic or highly aggressive fluxes. Eventually every tip will wear out and will need replacing when it becomes rough or pitted.

One of the best ways to do that is by tinning the tip. You should tin the tip of your iron before and after each soldering session to extend its life. Once the plating gets even a pin hole in it the molten tin will eat out the copper core of the tip.

Hold the solder to the tip while its heating up to make sure you tin the tip before it has a chance to turn black. It is not impossible to do point soldering with this tip but it is considerably difficult as compared to the other tips. Heres what you can do to keep your soldering iron working for years to come and prevent badly maintained solder tips from affecting your work.

What is the best soldering iron out there. Eventually they wear out. All tips eventually wear out due to heat and normal use.

Soldering iron tips wear out over time and unfortunately if your tool fails to transfer heat to the connection point effectively then it must be deemed unreliable and ultimately expendable. Iron like any material has its strong and weak points. But over time the oxidation process will wear out your soldering tips and you will need to re-tinner them.