How To Solder Two Thick Wires Together

THICK WIRE For large sculptures armatures- cuts best with a bolt cutter or saw.

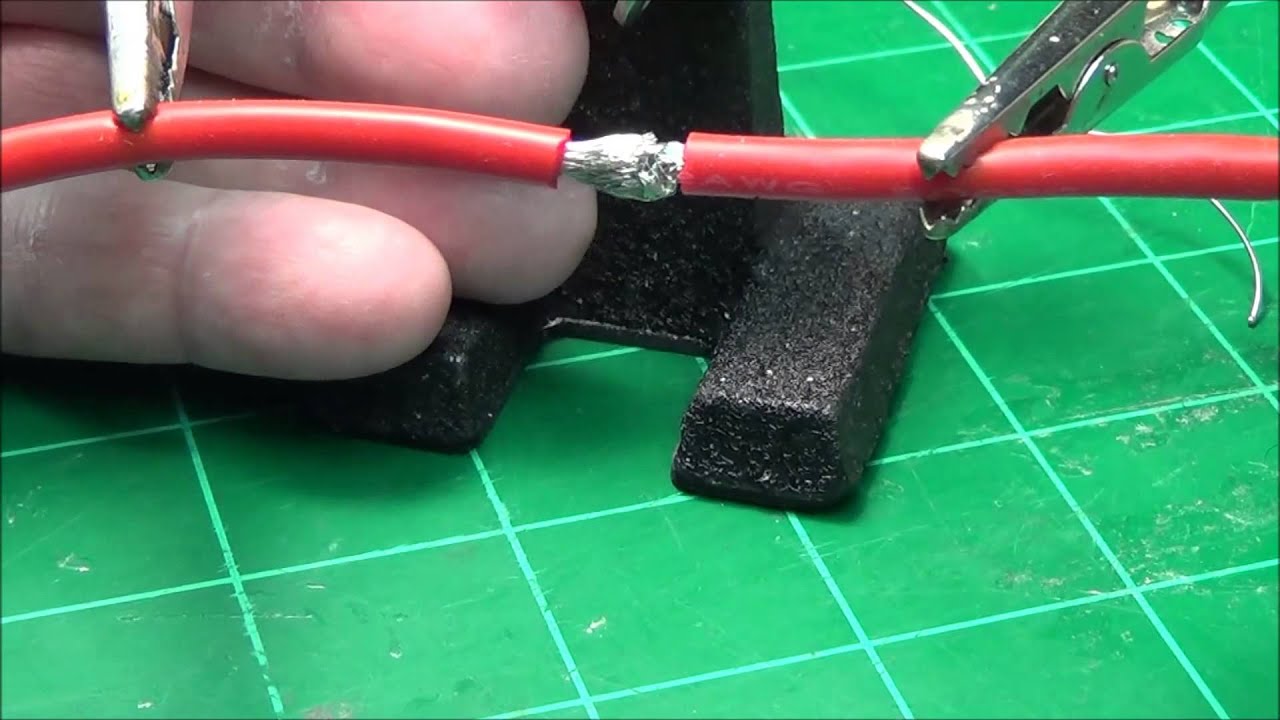

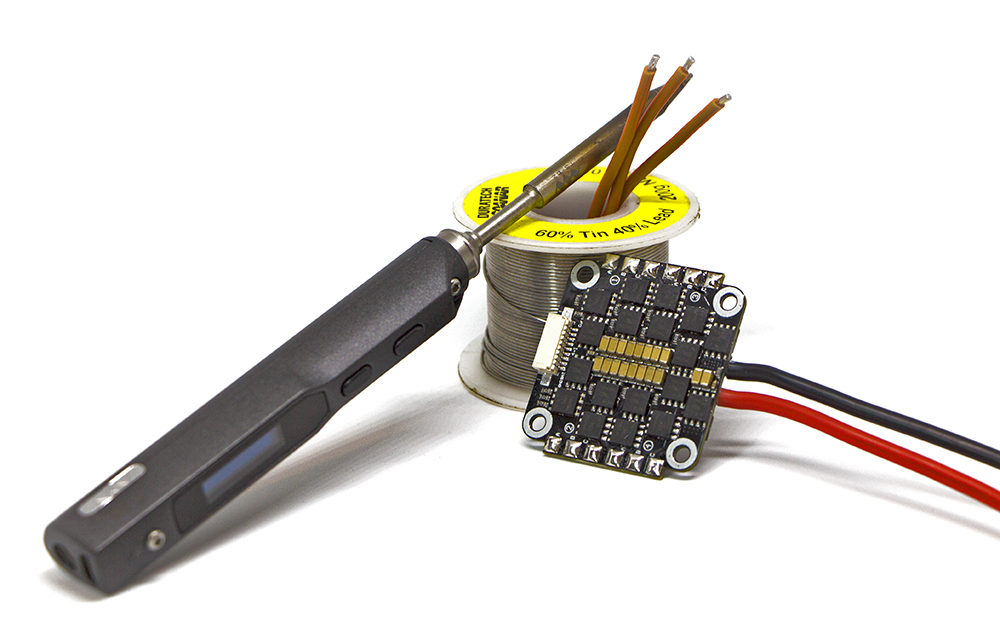

How to solder two thick wires together. Apply a drop of solder flux on top of the wire connection. The most secure and durable way to splice two wires together is to solder them. First your wire connection should always be mechanically sound before you solder.

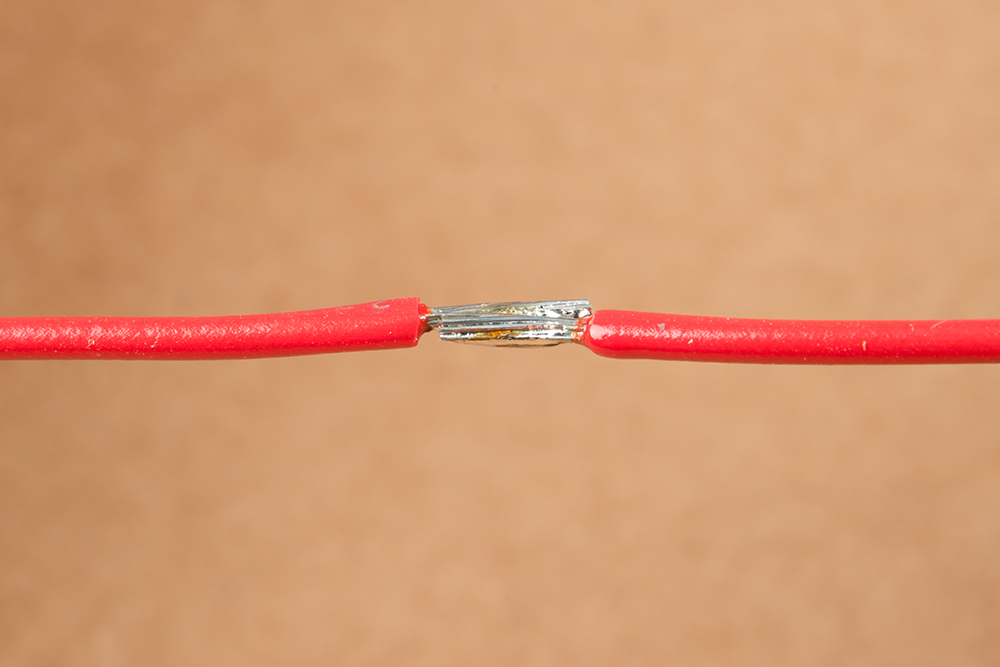

Extending the heat shrink about 12 to 1 passed the solder joint on both sides. Using a wire stripper or your micro flush cutters strip about half an inch of plastic insulation away from the ends of both wires. Real tidy with needle nose and only requi.

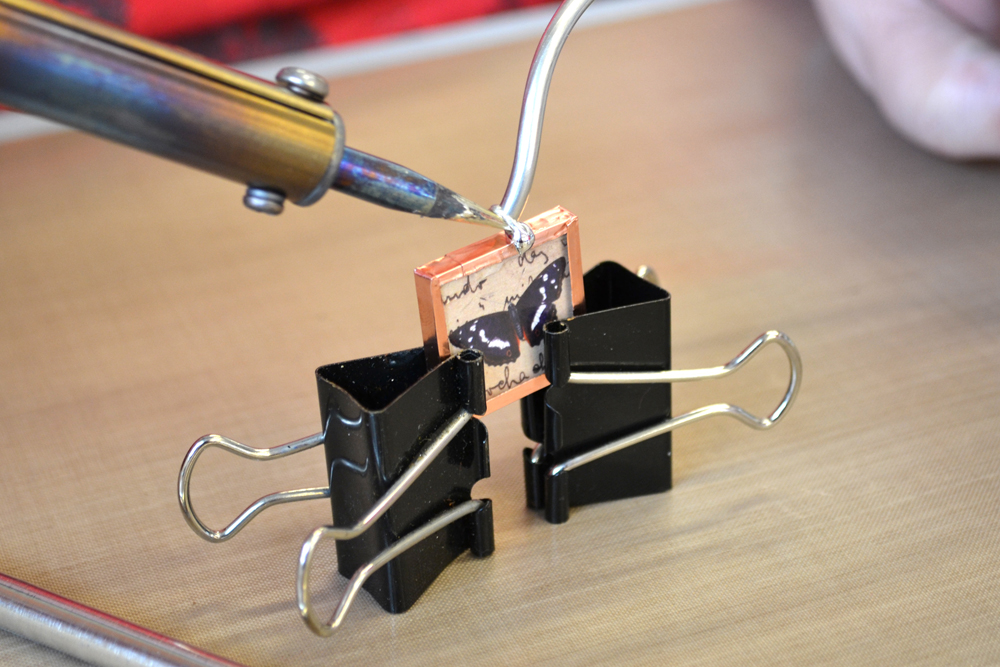

326 mm 9 114 inch 291 mm 10 102 inch 26 mm 12 081 inch 50 2 mm thick About as thick as a standard wire coat hanger 14 064 inch. Un-twist the strands fan out slide the ends strands together overlapping each of the strands so they intermingle roll this area splice in your hands fingers now solder the strands all together on masse. They should be propped up off the workspace so you can have access to the area under the wires.

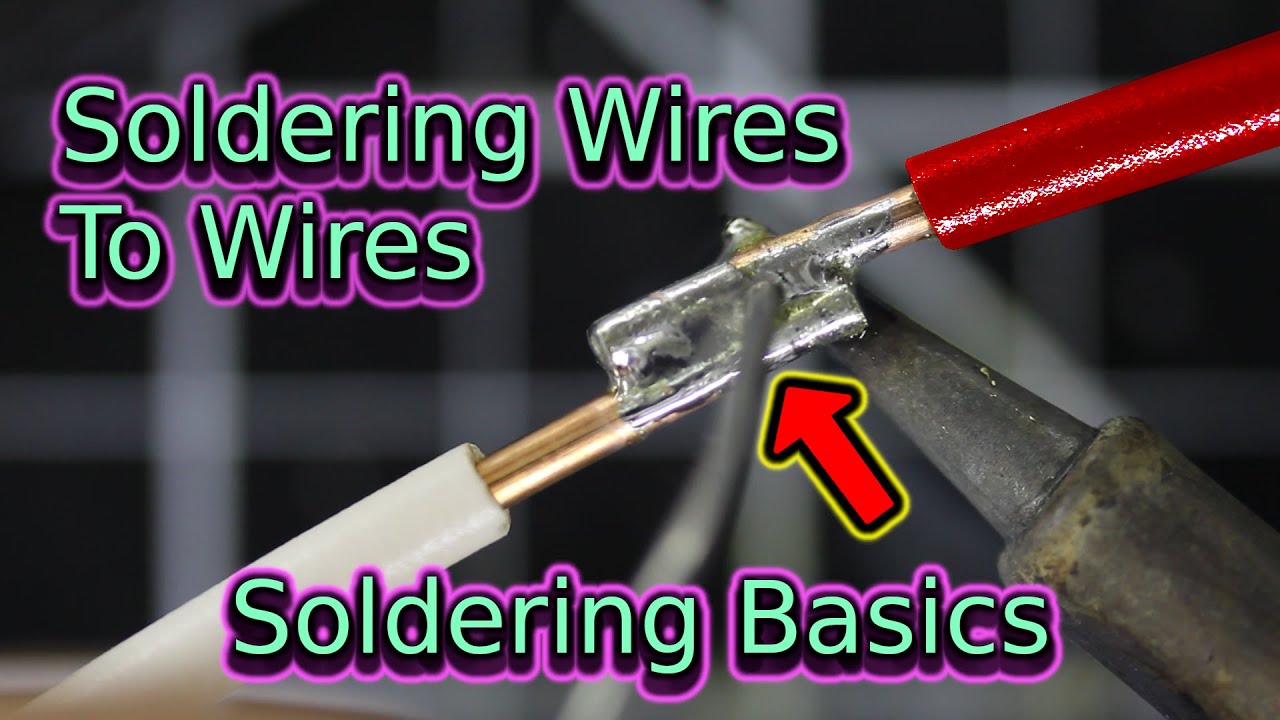

Heat up the joint and melt the solder with the wire not the soldering iron. Twist and fold 2. Tin the soldering gun ie melt a little solder on it.

3 Heat the shrink tube to make it shrink down around the wire. 8 128 a little over 18 inch. When done properly you have a strong conductive connection that turns two separate wires into one.

Repeat the tinning process on the other wire. Strip about 6 mm 14 from the end of the wire. Work from multiple angles and make sure to get thorough coverage.