How To Solder Fine Electrical Wires

Please dip the litz wire without removing enamel coating into the soldering jarpot.

How to solder fine electrical wires. The solder should flow freely into the wire and coat it. Its the act of using heat via a soldering iron and a fusible metal the solder to create the electrical connection. First you will have to strip off the insulator that covers the wires.

Begin by removing the insulation from the ends of both wires you are soldering together. There is one way to twist wires together for soldering- a horizontal twist that yields a continues length of. With a drop of solder on the iron you hold the wire in the drop and add a bit of resin core electronics solder and the wire will take the solder if a few moments.

If you use flux it must be for electronics any other will ruin the wire in a short time as most are acid. Remove the soldering iron and allow the soldered connection to cool and harden for a few seconds. If you did the cable and the tag at the same time by the time the solder properly melted the wire insulation would have started to melt.

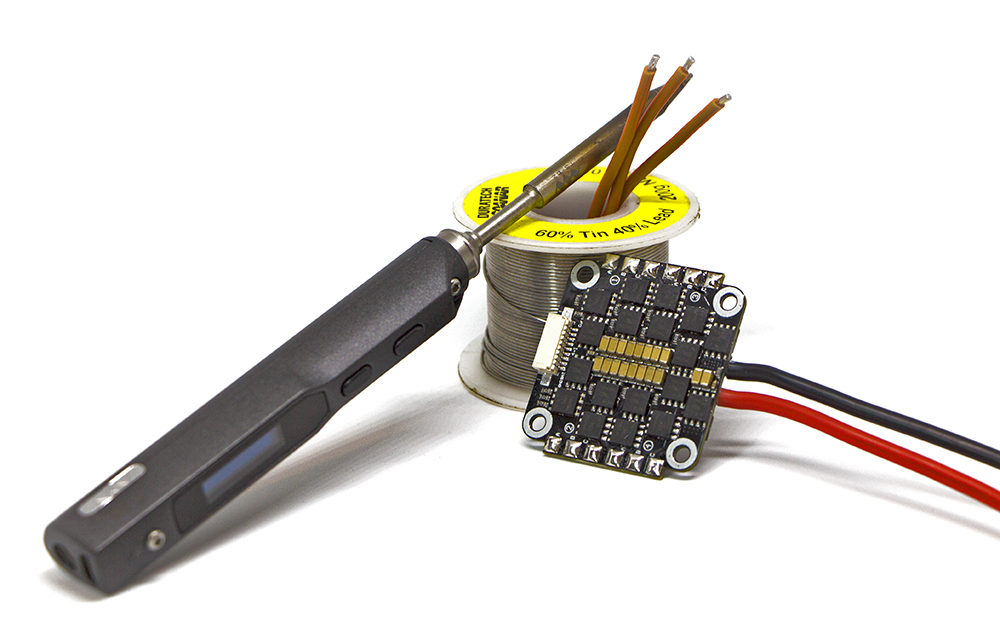

This process should melt the solder and coat both wires evenly. Then twist the filaments of each wire tightly to make them orderly. 60tinpine resin and 40lead.

The solder jar is made up by approx. If that is enammelled wire as it appears then as others have said the best method of stripping is to heat the ends with a flame to destroy the insulation and scrape off the residue. Tinning the tips of stranded wires holds the fine wires together and makes it easy to connect them to screw terminals or other connectors.

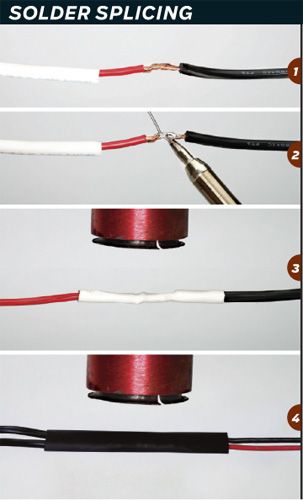

Do not put the solder on the iron tip as the tip will be hotter than the wire and the solder may not flow into the wire. The solder should be fed into the cool side away from the heat which allows it to be drawn in smoothly by the heat transfer through the wires. When doing splices clean the wires by scrapingbrushingsanding solder tin the wires to be joined slide clear heat shrink tubing over one wire lay the tinned ends together and touch them with the soldering iron and they will fuse nicely then slide the clear heat shrink tubing over the joint heat shrink one end pack it with petroleum jelly then heat shrink the other end.