How To Solder Automotive Wiring

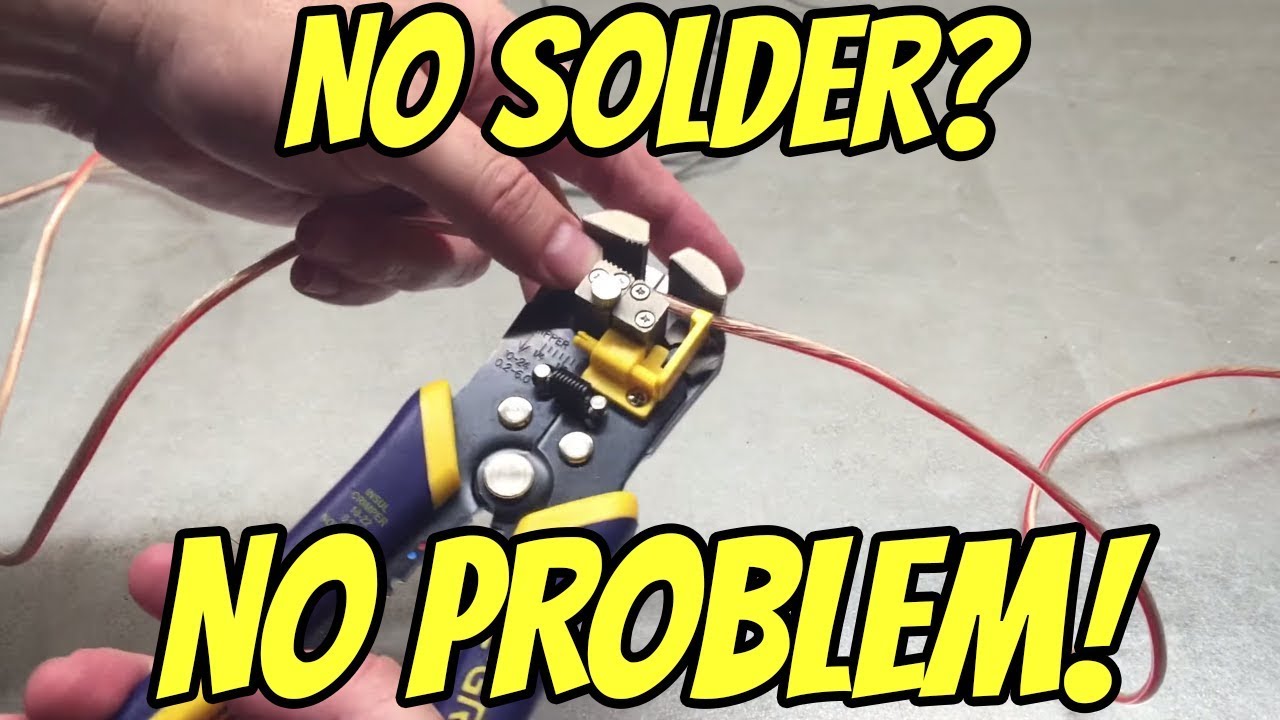

First strip the sections of wire you plan on soldering together.

How to solder automotive wiring. Tap the end of the 6337 solder on top of the wire splice so the solder melts down into the wires. A few tips and tricks to use when soldering is to first always make sure you do not have a cold solder joint make sure you are using the right solder for the job and always make sure you seal your solder joint from all types of weather. Try sourcing some alli solder it may work for your particular wire.

When soldering any connection it. This is good for. SOLDERING KIT INCLUDED60-watt digital soldering station with side-mounted solder roller holder removable built-in soldering iron holder to ensure soldering iron safety cleaning Sponge to remove solder residue for future use 2 helping hands to fix welded objects and solder tips holder to put solder tips.

Be sure to remove all of the damaged wire section. Automotive wiring should be soldered and protected properly in order to withstand all types of weather rain snow and salt. Dead link also not available on the Wayback.

Place the soldering iron underneath the wires and apply the solder from the top. Once the connection evenly turns the correct silver color of solder remove the soldering iron and allow the joint to cool. If your re-wiring your car or truck then this is a MUST Video For YOU.

Remove the soldering iron and wait a few seconds to let the soldered. Electrical tape or PVC shrink tube. Apply enough solder so that every strand of wire is surrounded by solder.

A 40-watt iron is good for automotive parts while a 15-watt iron is well suited for thin wires and circuit boards. Outer diameter of single core wire. Automotive-grade stranded wire thats the same gage as the old wire.