How To Remove Silicon Oxide From Iron

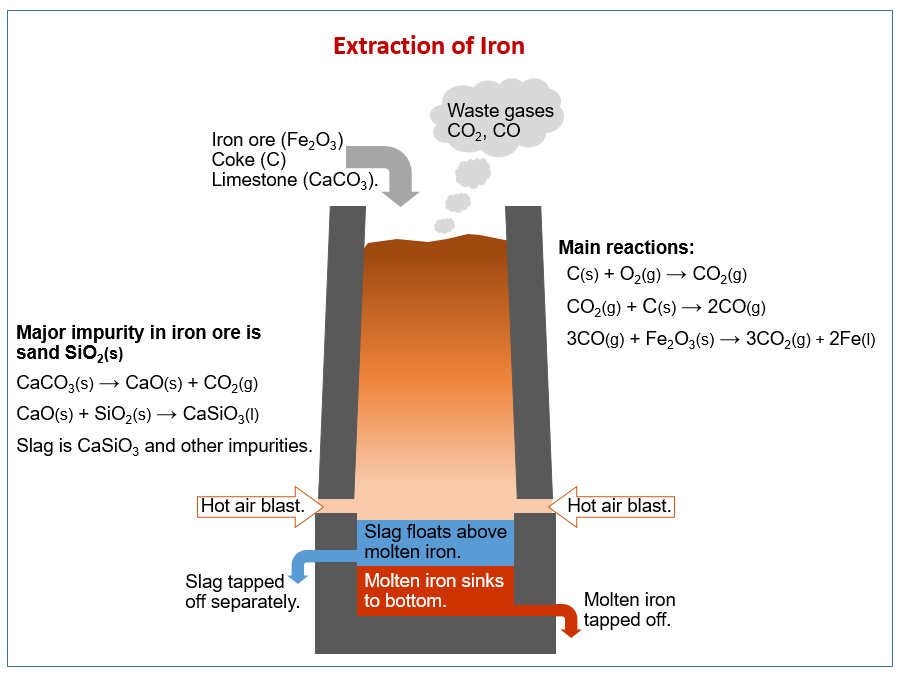

2Fe 2 O 3 s 3Cs 4Fel 3CO 2 g In this reaction the ironIII oxide is reduced.

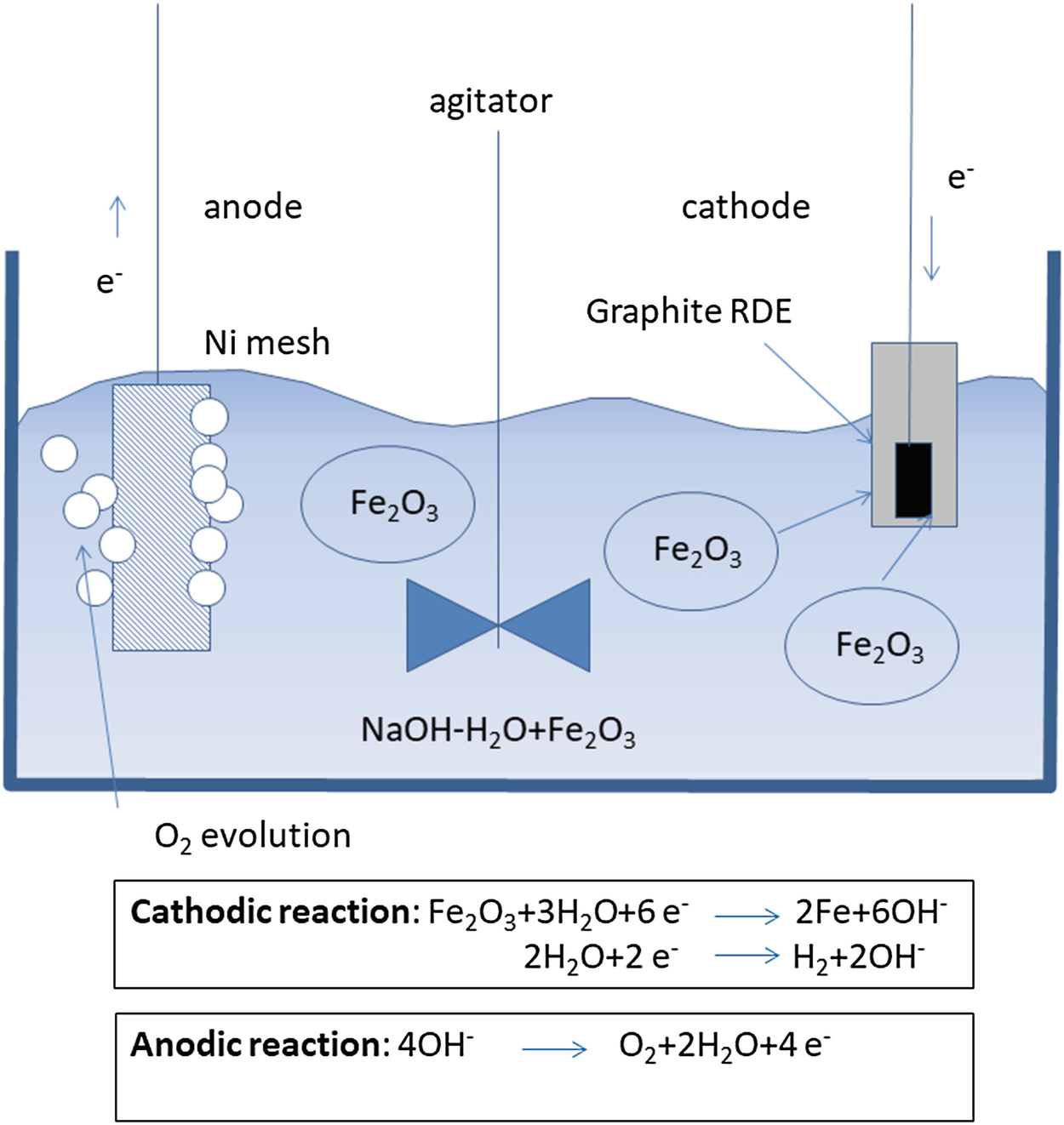

How to remove silicon oxide from iron. Example 2The same method steps as described in Example 1 were practiced on a Quebec Cartier iron ore concentrate of minus 65 mesh containing initially 3 silica. A better wood bleach that can leach out minerals is a mixture of sodium hydroxide drain cleaner and hydrogen peroxide. Using magnesium compounds during the hot lime-soda process of softening and recirculating the sludge.

The silicon oxide is removed by exposing a semiconductor structure comprising a substrate and. Pressure every fifteen minutes. You may try the famous Bayer process which is used for extracting alumina form bauxite.

A method of removing at least a portion of a silicon oxide material is disclosed. So this is a possibility for the chemical removing of iron oxide from silica sand. CaO s SiO 2 s CaSiO 3 l.

The removal of alumina and silica from iron rejects slime Jan 01 2011 A hydrometallurgical method of alumina and silica gangue removal from rejects slime of iron ore by alkali and acid leaching is proposed Up to about 80 gangue is removed by chemical leaching with sodium hydroxide sulphuric hydrochloric and nitric acids. Therefore it is advisable to use the dry cleaner options to avoid shock do a faster job and increase the life of the iron tip. You can remove oxides easier by wiping the soldering iron tip in a wet sponge.

Factory price biogas h2s scrubber Iron Oxide desulfurizer to remove H2S for Biogas Purification Biogas scrubberMore information please contact with us Mob. 2306021 describe the said principle for the first time in their application dated 1940 and describe a process for removing iron oxide from natural silicon dioxide sand which includes converting the iron oxide into a soluble iron salt by the action of an acid solution containing sulfuricMar 13 2010 The ore is loaded into a blast. Be careful not to get a thermal shock while doing this.

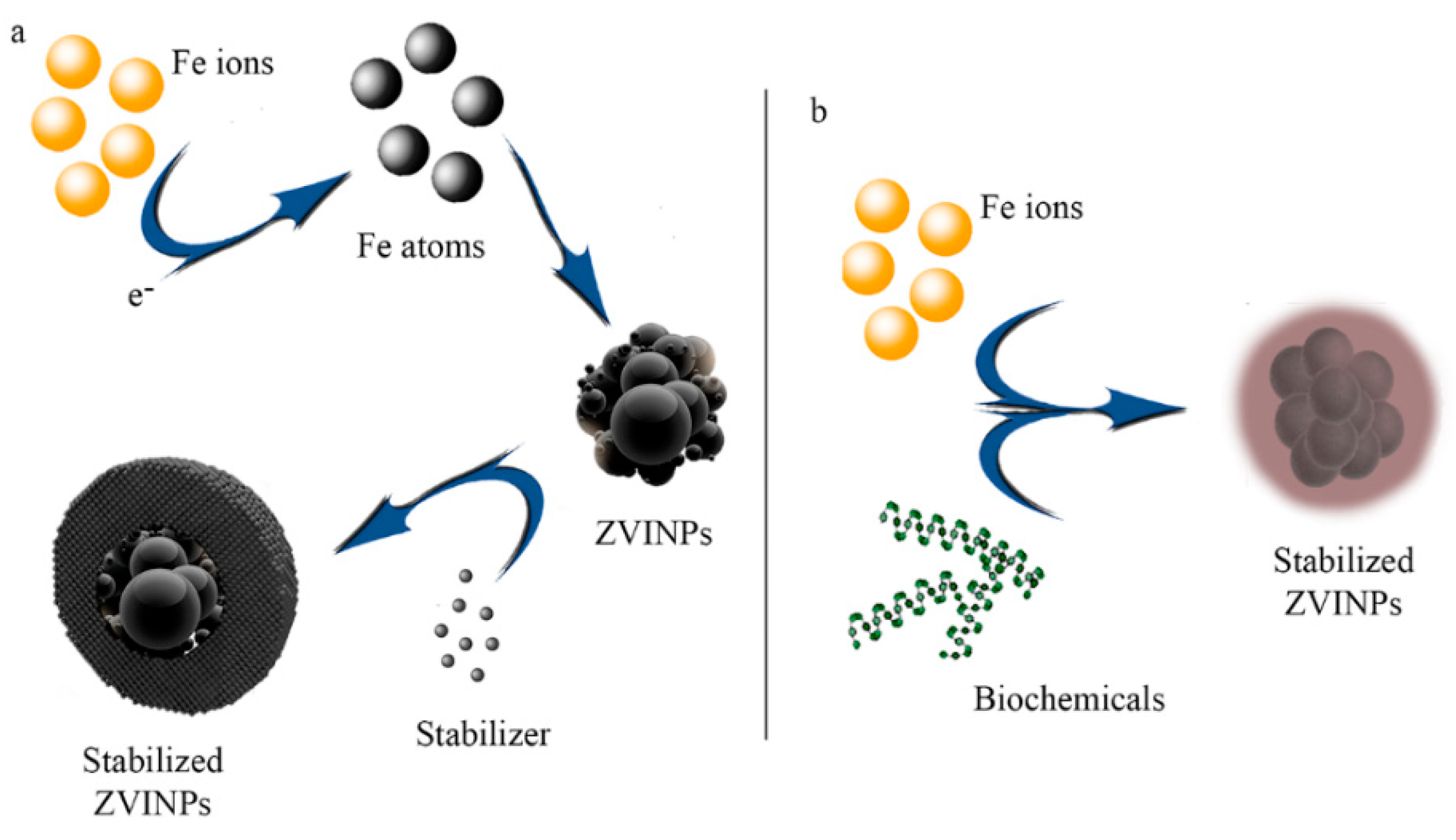

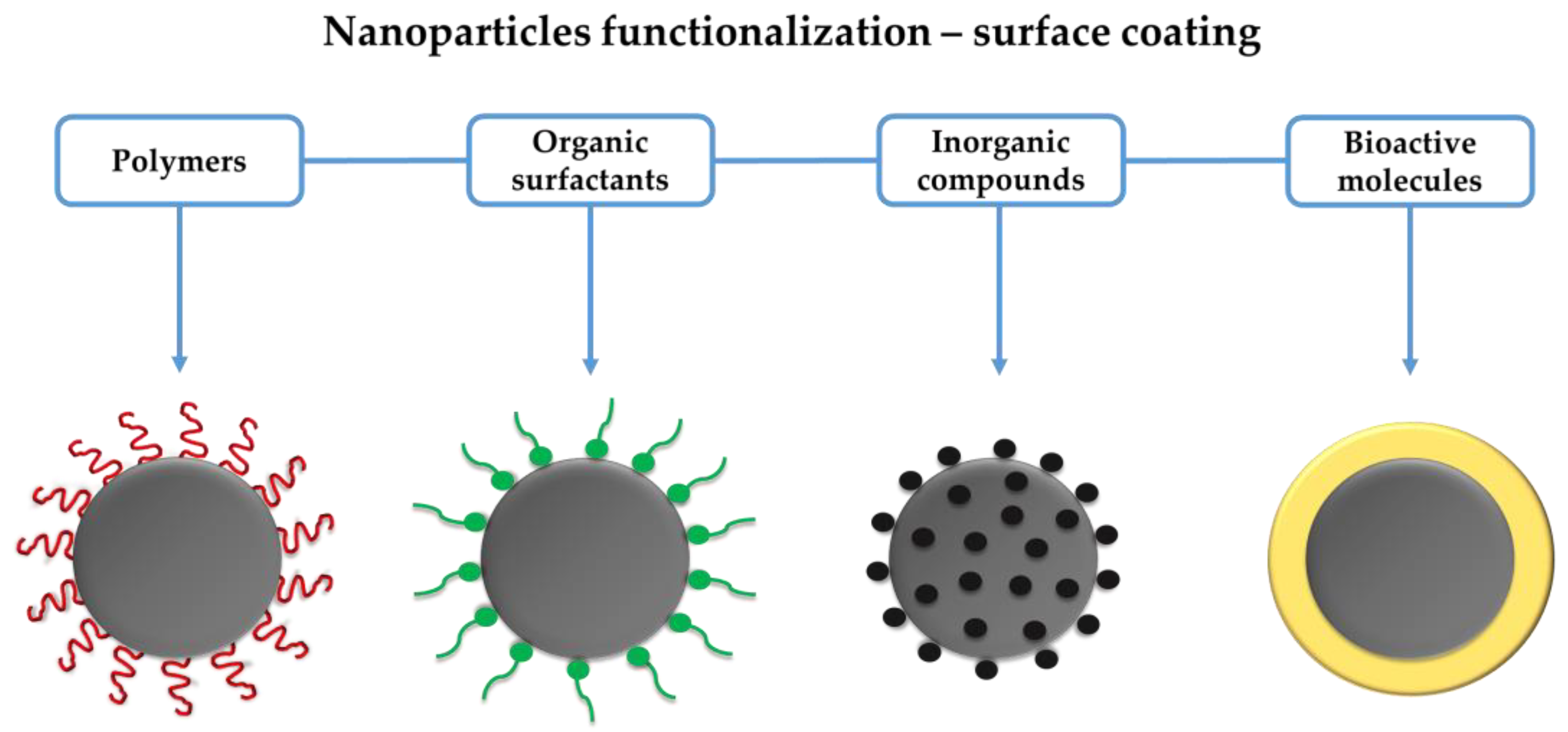

After magnetic separation to remove the remainder of the liberated particles it was found that the resulting concentrate had a silica content of 4. Some rust was thus broken off and washed away but the results were not satisfactory. The synthesis of FeSi mixed oxide nanocomposite materials in which the iron III oxide is the major component is described.