How To Make Soldering Iron With Good Night

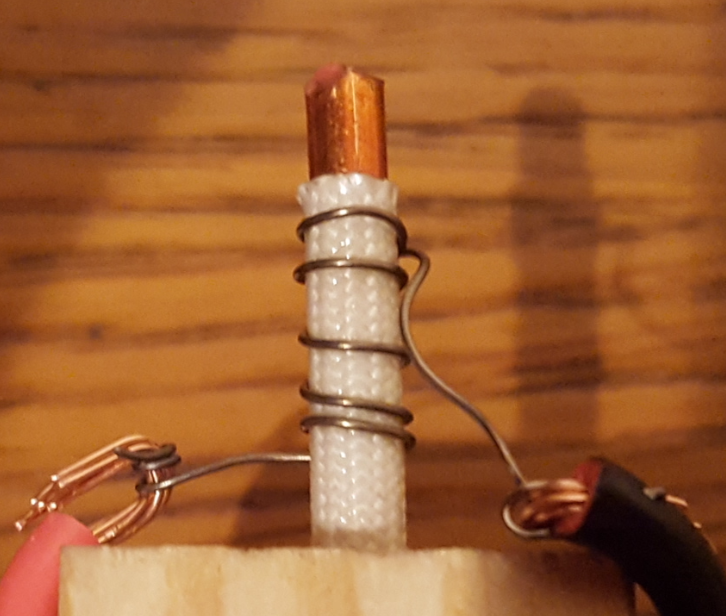

The barrier material prevents the copper and tin.

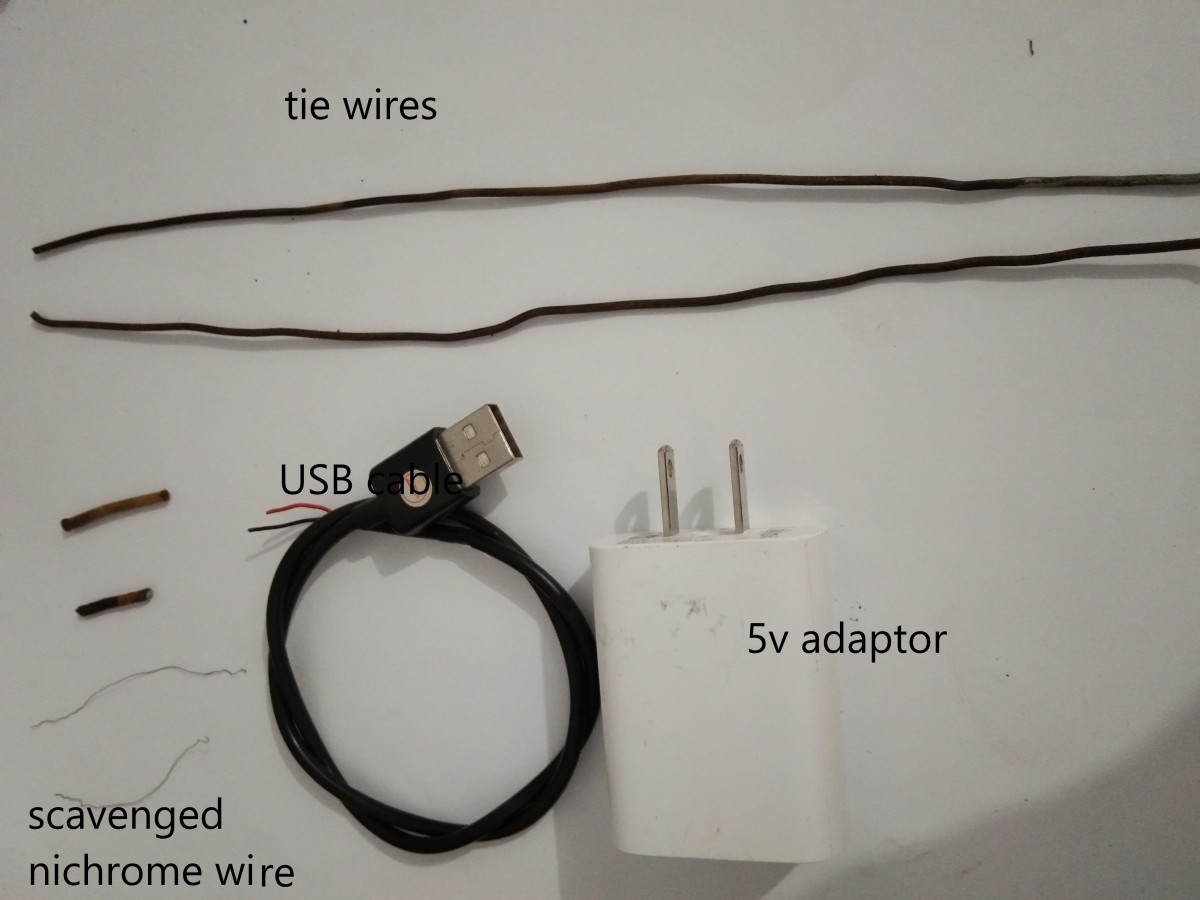

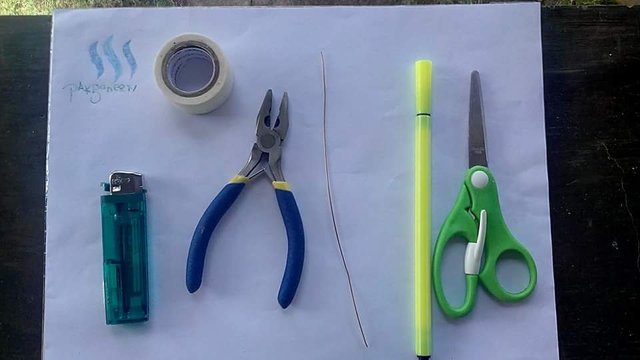

How to make soldering iron with good night. In a recent study which appeared in the Lead-free Update by Tech Search International in December 2004 hand-soldering was found to be more problematic to implement when compared to lead-free wave soldering and SMT. Ad Compare a Huge Selection of Parts. Wait a few seconds to let the tip heat up again before proceeding to step 4.

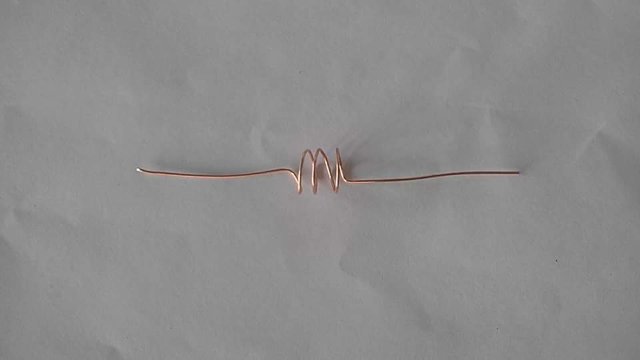

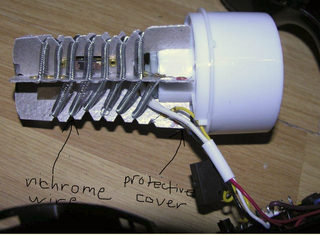

You need to clean and then tin the tip. 7Iso-Tip SolderPro 50 Soldering Iron. The iron and the nickel create a barrier between the copper base material and tin used in the solder alloy.

When soldering multiple header pins make sure the first pin is straight. If the solder does not flow heat the joint for another second or two and try again. Wet the soldering station sponge with the water provided in the lab.

Use High Quality Solder. Remove solder iron and let it cool down. Right It only takes a second or two to make the perfect joint which should be nice and shiny.

Plug in the soldering iron turn it on and let it warm up for 23 minutes. Then an iron electroplate goes over the nickel. Used for soldering iron tips.

It should melt and flow smoothly onto both the pin and the pad. Ad Compare a Huge Selection of Parts. Remove the iron and allow the solder joint to cool naturally.