How To Make Homemade Soldering Flux

Good for perhaps 200 smd joints.

How to make homemade soldering flux. Hi Stan To clean flux after soldering you can wash each panel as you finish it in warm soapy water. Pinecone flux can be made with 10-15 pinecones and some denatured ethyl alcohol. Ad Octopart Is The Preferred Search Engine for Electronic Parts.

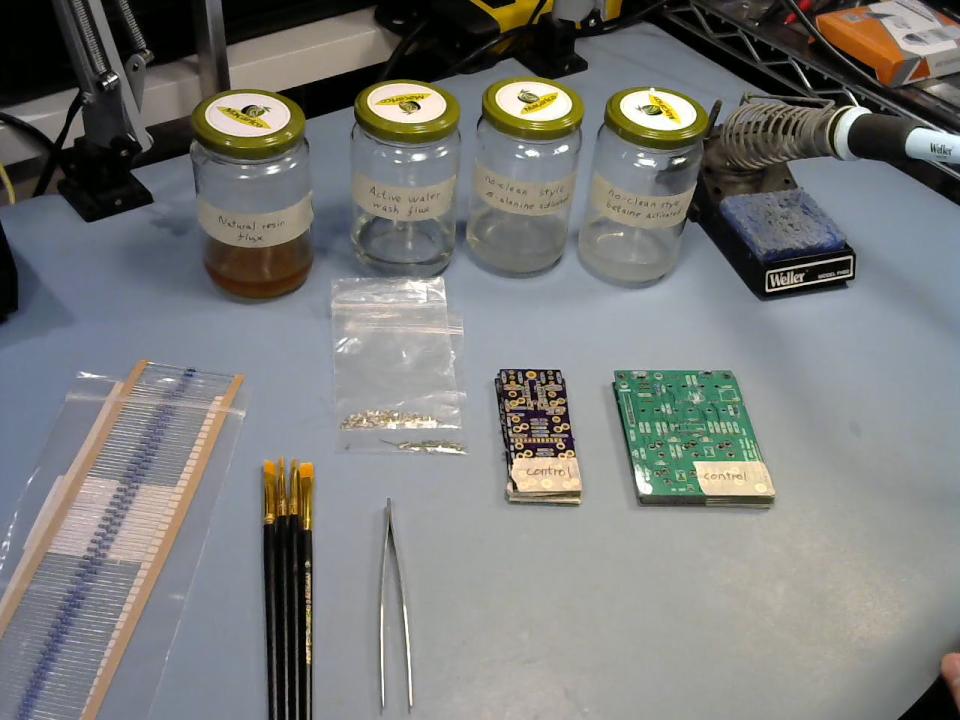

So thats 32 oz. Some fluxes are corrosive so the parts have to be cleaned with a damp sponge or other absorbent material after soldering to. In previous videos we compared different types of commercial flux but did you know its possible to make a simple and effective flux at home.

Do nothing until all of the juice has strained through. The natural pine tar in the cone leaves works as a flux and can be extracted. In the soldering of metals flux serves a threefold purpose.

You have made one litre of flux remover that quantity should suffice for quite some time. How to make soldering flux at home. If possible use a strong detergent and small brush toothbrush to.

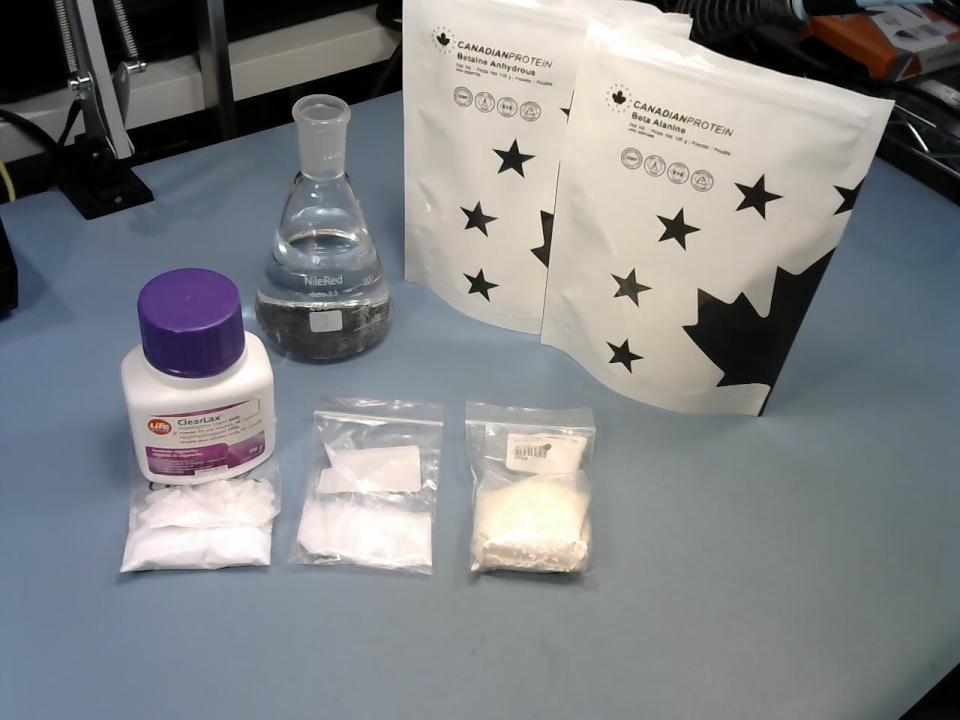

Add your solvent start with a small amount and keep adding until you are happy with the way your flux behaves. Take a liquid measuring cup and pour off 150ml of the Ethanol from the container. Stir the juice in the container for 10 seconds with the wooden spoon.

Aqua and the s means it is in solid form. Add 100ml of Isopropyl alcohol and 50ml of Ethyl acetate to the 850ml of the Ethanol in the container. Cover the container and allow the mixture to sit for at least 8 to 12 hours.