How To Improve Soldering Process

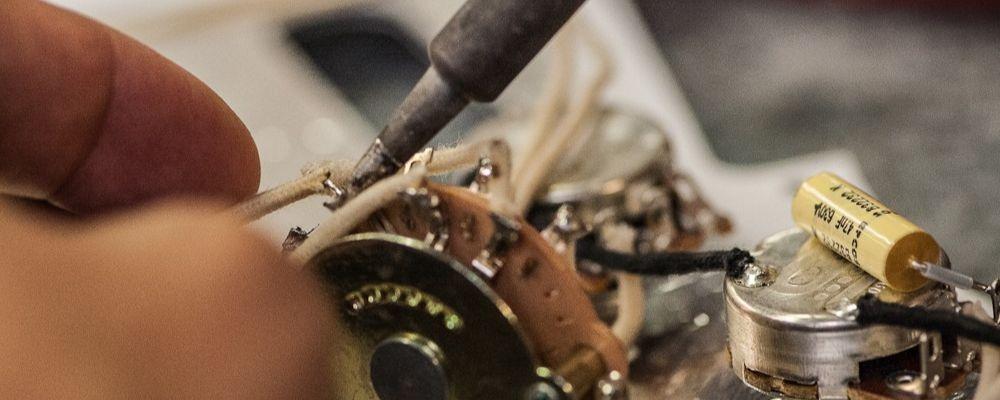

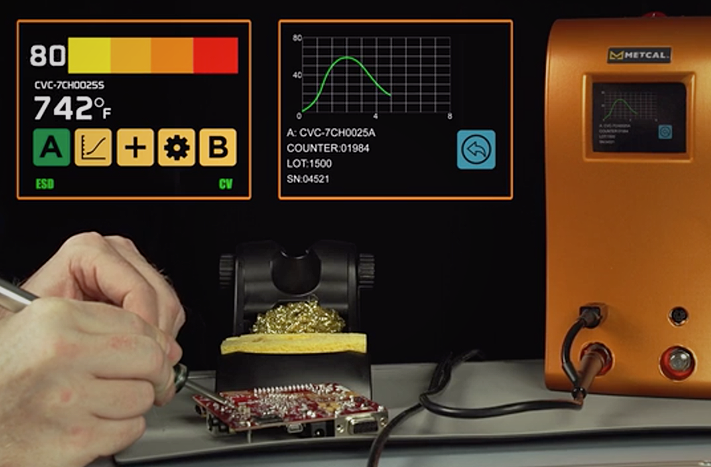

Quality solder joints are a combination of proper technique as well as proper soldering.

How to improve soldering process. Before you can start soldering you need to prepare your soldering iron by tinning the tip with the solder. This process will help improve the heat transfer from the iron to the item youre soldering. Apply mechanical structure to support the board.

After cleaning wipe the tip with moist cotton or sponge. Good soldering is influenced by how clean the tip of your soldering iron is. A hot nitrogen air knife will force the solder to flow in the opposite direction and eliminate bridging.

Before you can start soldering you need to prep your soldering iron by tinning the tip with solder. The hot air heaters blow hot air over the PCBs before they pass towards the wave soldering machine. In the soldering of bare copper OSP with lead-free alloys such as SnAgCu or SnCu the following can be tried to improve hole-fill.

However there are different ways one can use in order to improve the soldering skills. Before starting tin the soldering tip by adding fresh wire solder to it. In a drag process a stable solder flow is critical.

The basic principle is to make the amount of solder ball printed in the outermost row or four corners of the BGA more than that of the remaining solder balls. Tinning also helps protect the tip and reduce wear. Once the solder begins to flow to the back side along with the direction of the board bridges will begin to appear.

Never set the soldering iron down on anything other than an iron stand. To change the amount of solder paste of the BGA you can start from Stencil. This includes solder ux alcohol and desol-dering braid.