How To Improve My Stick Welding

Remove the welding stinger from the electrode as fast as you can turn off the welder and break off the rod from the metal.

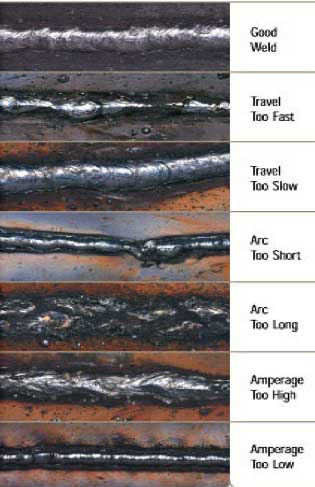

How to improve my stick welding. The DCEP polarity increases the weld bead width by increased globular metal transfer. Current setting length of the arc angle of electrodemanipulation of electrode and speed of travel. As a general starting setting I use one amp per thousandth of an inch thickness of the electrode.

Current setting length of arc angle of electrode manipulation of the electrode and speed of travel. A steady hand makes for a better weld and better lookingWhen taking a 6G test Id always stick my file or wire brush handle in the cupon or somthing. When stick welding for the first time most people find it logical to have a long arc usually to have a better view of the weld puddle.

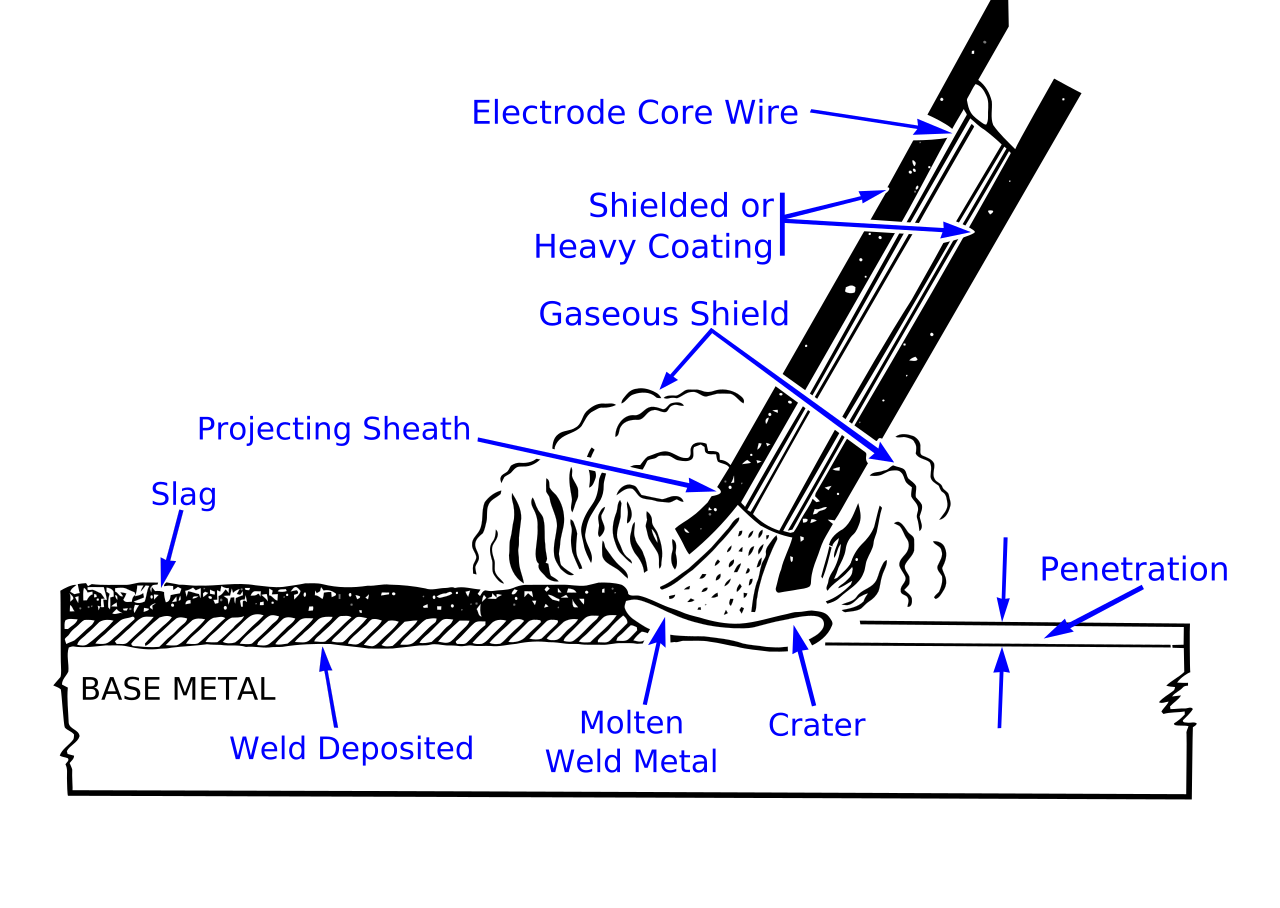

At this stage the only thing you can do is to break off the rod from the metal the tip of the electrode which includes the flux might fall off but you dont need to worry too much about it. If youre just learning the stick process technically called shielded metal arc welding SMAW remembering these five points will improve your welding technique. 13 Surefire Ways to Improve Your Stick Welding Skills 1Be able to clearly see what you are welding If you are using a welding mask or helmet with dirty or scratched lenses it is probably time to replace them.

Skill comes only with practice. A beginning stick welder can produce better welds by paying attention to the five basic elements to establish a good consistent technique. I would start around 125 amps and make a test weld.

Shellfish can make you a better welder. Vertical up or 3G point the rod up between 30 to 45 degrees. The following pages will help the inexperienced welder to understand welding and develop his skill.

I hope someone can use this tidbit. With the correct current set on the welder machine you should get smooth neat welds with little or no splatter. While stick welding may be the most forgiving process on dirty or rusty metal dont use that as an excuse for not properly cleaning the material.