How To Fix Oxidized Solder Tip

You simply coat the tip in the paste and then wipe it off.

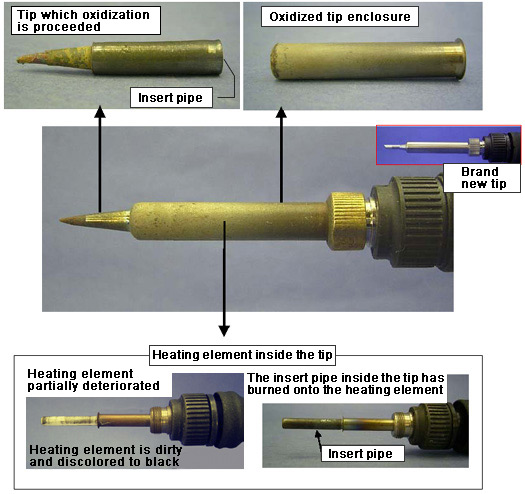

How to fix oxidized solder tip. A polyurethane foam bar with embedded abrasives which is used to polish the working end of the tip to remove surface oxides. In this way you can adjust the variac control and get a feel for the precise temperature that will create a good solder flow and yet maintain a reasonably clean iron tip. Tip life -Point 3-SOLDERING IRON.

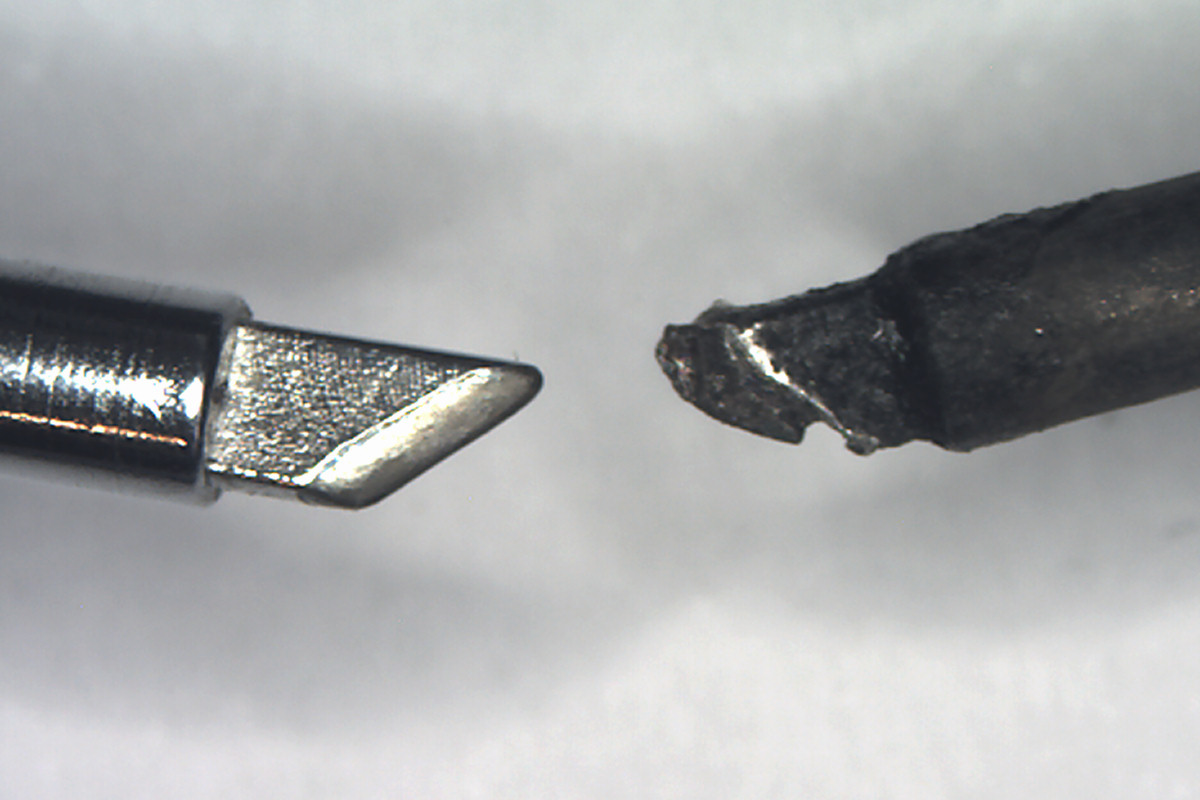

Turn it off as soon as you have finished soldering. Unroll a portion of solder then roll the hot tip of the iron from the end of the solder until it does one complete turn on the solder. Then heat the tip and apply the Solder.

If the tip temperature is too high oxidation occurs. Repeat the steps above until the tip is clean. Please note that the FS-100 should not be used for other purposes apart from restoring the soldering tip.

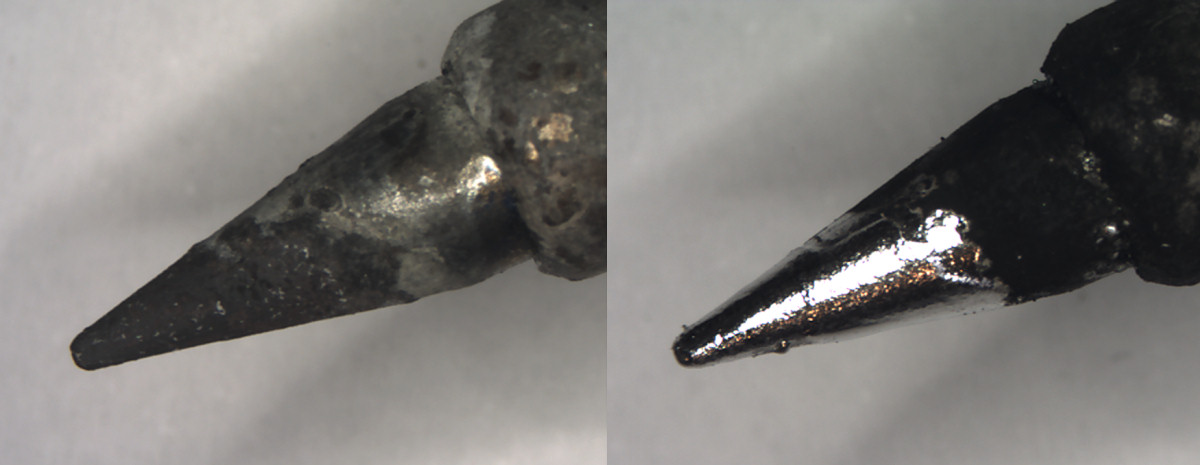

You can remove oxides easier by wiping the soldering iron tip in a wet sponge. The heat will activate the flux and start the chemical reaction that will remove the oxidation. Overheating the tip Your soldering iron should be set to 100C of the solders melting point.

Maintenance and inspection of soldering pots. Try not to leave the iron sitting hot on the bench while not in use. Offset Value Input Methods.

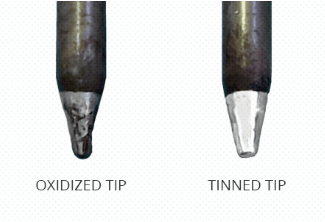

This means that after every soldering operation you clean your soldering tip dry wet and then tin it before you put the soldering iron back in the tool holder. How to clean an oxidized soldering tip. Dip the tip into the tinner making sure that the entire oxidized surface is in contact with the re-tinning product.