How To Carve A Wood Sign Larger Than Your Cnc Router

The larger the bit the faster you can run the machine and cut out your design.

How to carve a wood sign larger than your cnc router. CNC Router users this is your CNCCookbook home page for information and resources. Other CNC routers may have other types of buttons to signal this command. If you are flattening large boards or you are responsible for maintaining the spoil board on your CNC router youll want to have a spoil board cutter or flycutter bit.

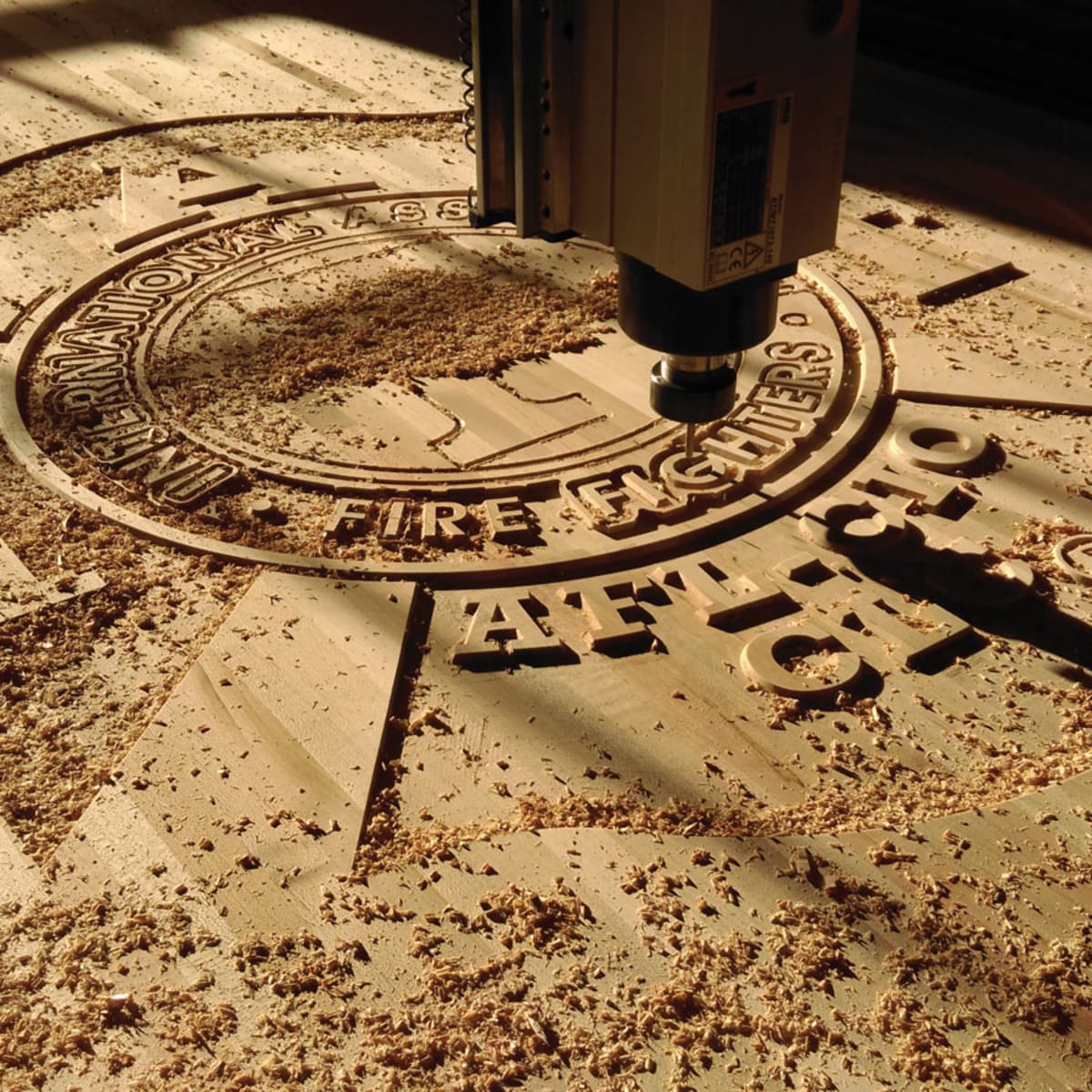

Thankfully most programs including the one we used will show a simulation of the cut and let you know if the bit you choose will cut out the shape or if its to large and you need to use a smaller bit. It will return to its home position when the engraving is complete. Sign making is definitely one route that a woodshop can take to turn an idle CNC router into a profitable investment.

These bits are made to skim the surface and leave a smooth flat finish. It has a flat-edge tip that leaves you with a better edge quality than other bits. CNC routers have a simple task etch the surface and carve the design.

Assume that you need. We can carve laser engrave and sandblast your sign. This is due to the weather elements.

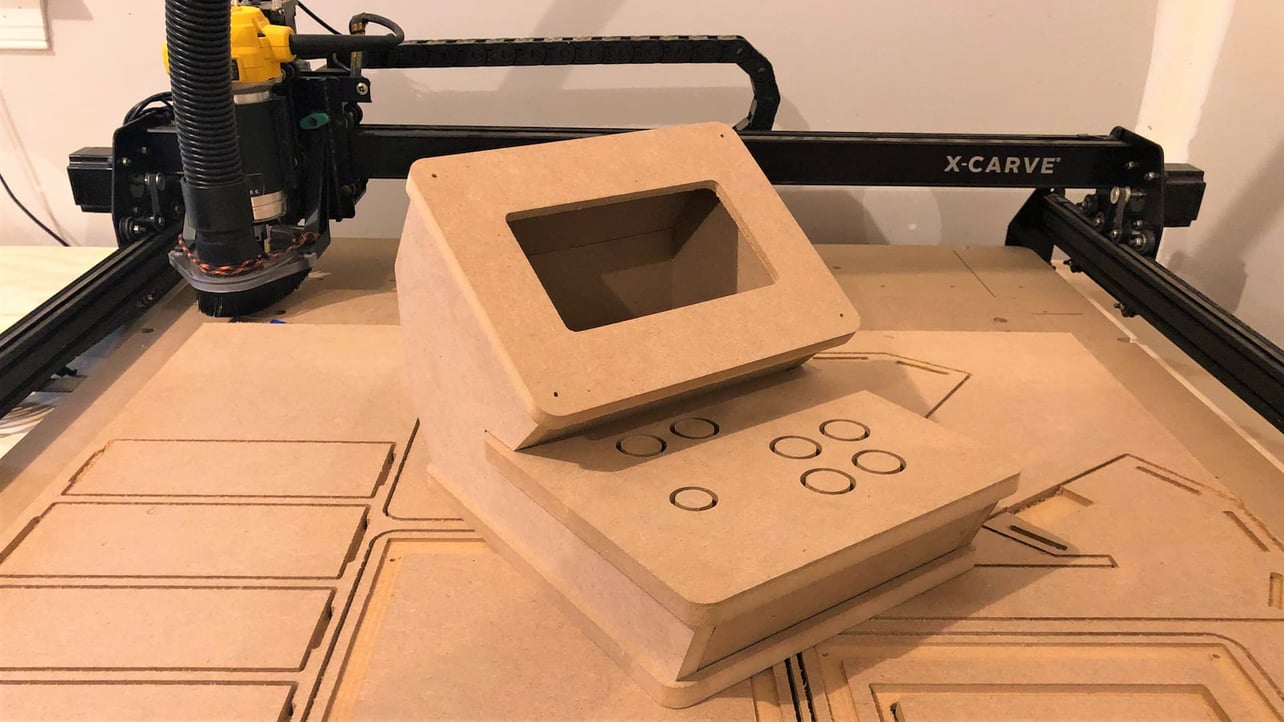

The CNC wood router can do many different type of works on wood such as 2D 3D routing cutting carving drilling grooving or milling. Ad sign is a necessary need for nearly every business. Ornate cabinet doors carved insets all can be programmed on a CNC router delivering a timeless hand carved look at a fraction of the time and cost.

This is the second DIY CNC Router I made after learning a lot from building the first version. This process is also invaluable if the maximum sizes of your material pieces are limited. Custom Wooden Name Signs.